Understanding Plastic Injection Molding Machines

Plastic injection molding machines are essential tools in the manufacturing landscape, transforming raw plastic materials into a vast array of products ranging from simple household items to complex automotive components. The versatility and efficiency of these machines make them a cornerstone of modern industrial production. As the industry evolves, manufacturers are increasingly investing in advanced technologies that enhance precision, reduce costs, and address environmental concerns. When exploring options, plastic injection molding machine solutions provide comprehensive insights into features and innovations that can drive operational excellence.

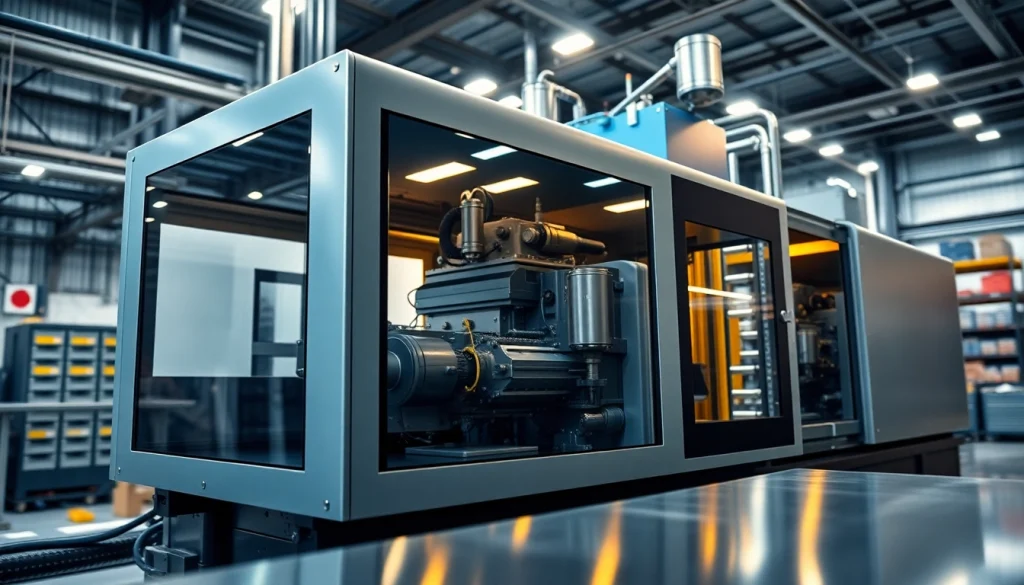

1. What is a Plastic Injection Molding Machine?

A plastic injection molding machine, often simply referred to as an injection molding machine, is a mechanical device that produces solid plastic parts by injecting molten plastic into a mold. The process begins with heating plastic pellets until they reach a molten state, after which they are injected into a mold at high pressure. Once cooled, the mold is opened, and the final product is ejected. This method allows for the mass production of identical parts with high precision, making it ideal for industries such as automotive, consumer goods, medical devices, and more.

2. Types of Injection Molding Machines

There are several types of injection molding machines, each designed to cater to different manufacturing needs:

- Hydraulic Injection Molding Machines: These machines utilize hydraulic pressure for the injection process. They are known for their power and are often used for larger, heavier products.

- Electric Injection Molding Machines: Offering higher precision and energy efficiency, electric machines use electric motors to drive all movements, making them ideal for intricate designs and rapid production cycles.

- Hybrid Injection Molding Machines: Combining the benefits of hydraulic and electric systems, hybrid machines provide a balance of speed, energy efficiency, and power, suitable for diverse applications.

3. Key Components and Their Functions

Understanding the components of an injection molding machine is crucial for effective operation and maintenance. Key components include:

- Injection Unit: Responsible for melting the plastic and injecting it into the mold. It contains a hopper for raw plastic, a barrel to melt it, and a screw mechanism to inject it.

- Clamping Unit: Holds the mold in place during injection. This unit must provide sufficient force to resist the pressure of the injected plastic.

- Mold: The cavity into which the molten plastic is injected. The design of the mold directly affects the shape and quality of the final product.

- Control System: Manages all machine functions, including temperature, injection speed, and pressure settings. Advanced systems may offer real-time feedback and automation capabilities.

Advantages of Electric Injection Molding Machines

Electric injection molding machines are becoming increasingly popular due to their distinct advantages over traditional hydraulic machines. Their rise in the market is driven by specific benefits that align with evolving manufacturing demands.

1. Energy Efficiency and Cost Savings

One of the primary advantages of electric injection molding machines is their energy efficiency. Unlike hydraulic machines, which consume a significant amount of power, electric machines use less energy by employing servo motors. This efficiency translates into lower operational costs, making it easier for manufacturers to maintain competitive pricing while enhancing profit margins.

2. Precision and Consistency in Production

Electric injection molding machines provide superior precision because the electric motors offer more accurate control over the injection process. This capability ensures consistent part quality, which is critical in industries that require tight tolerances, such as aerospace and medical manufacturing. The enhanced repeatability also minimizes waste, further optimizing production costs.

3. Environmental Benefits of Electric Machines

With increasing emphasis on sustainability, electric injection molding machines contribute to greener manufacturing practices. They reduce energy consumption, which not only cuts costs but also lowers the carbon footprint of the facility. Additionally, many electric machines have reduced hydraulic fluid requirements, minimizing the risk of spills and associated environmental hazards.

Choosing the Right Plastic Injection Molding Machine

Selecting the right plastic injection molding machine is a critical decision for manufacturers. Several factors must be considered to ensure that the chosen machine aligns with production needs and goals.

1. Factors to Consider When Selecting a Machine

When evaluating options, manufacturers should consider:

- Production Volume: High-volume production lines may benefit more from efficient electric machines, while lower-volume operations might find hybrid options preferable.

- Product Complexity: Complex parts with intricate designs often require machines that offer high precision and versatility, such as servo-driven or all-electric models.

- Budget Constraints: While electric machines offer long-term savings, their upfront costs can be higher. Manufacturers should assess their financial capabilities and long-term production goals.

2. Evaluating Machine Specifications

Understanding machine specifications is crucial for selecting the right model. Key specifications to evaluate include:

- Injection Pressure: This determines how forcefully the molten plastic is injected and is essential for achieving part density and quality.

- Clamping Force: The force applied to keep the mold closed during injection. Insufficient clamping force can lead to defects.

- Cycle Time: The time required to complete one cycle of the injection process, impacting production efficiency.

3. Understanding Manufacturer Reputation and Support

Choosing a reputable manufacturer can significantly affect the success of an injection molding project. Considerations should include:

- Support and Maintenance: Good support is crucial for minimizing downtime. Look for manufacturers that offer robust after-sales service and maintenance options.

- Customer Reviews: Research customer feedback and case studies to gauge the reliability and performance of specific machines.

- Innovation: Companies that consistently update their technology are more likely to provide advanced solutions that incorporate the latest manufacturing trends.

Best Practices for Operating Injection Molding Machines

Operating injection molding machines effectively requires adherence to best practices that enhance performance, prolong the machine’s lifespan, and ensure product quality.

1. Setup and Calibration for Optimal Performance

Proper setup and calibration are vital to achieving optimal performance. This involves:

- Temperature Settings: Ensure that barrel and mold temperatures are set correctly based on the material being used.

- Injection Speed and Pressure: Adjust these parameters according to the product requirements to ensure quality and minimize waste.

- Regular Testing: Conducting trial runs with the actual material can help in fine-tuning settings for best results.

2. Maintenance Tips for Longevity

Regular maintenance of injection molding machines is essential for their longevity and consistent performance. Key maintenance tips include:

- Routine Cleaning: Keep the machine clean to prevent contamination. Regularly check for and remove any plastic residue from the injection unit.

- Inspecting Components: Regularly inspect and replace worn parts to prevent breakdowns and costly repairs.

- Hydraulic Fluid Checks: For hydraulic machines, ensure hydraulic fluid is at the correct level and replace it as needed to avoid operational issues.

3. Troubleshooting Common Issues

Even the most sophisticated machines can experience issues. Common problems include:

- Short Shots: Occur when insufficient material is injected. Adjusting injection speeds and pressures can often resolve this issue.

- Bubbles or Voids: These can arise from air trapped in the material. Ensuring proper vacuum settings during the process is key.

- Mold Wear: Regular inspection and maintenance can reduce mold wear and preserve product quality over time.

The Future of Plastic Injection Molding Technology

As the manufacturing industry continues to innovate, the future of plastic injection molding technology looks promising with emerging trends poised to shape it significantly in the coming years.

1. Emerging Trends in 2025 and Beyond

Future developments in plastic injection molding include:

- Increased Automation: Automation will play a larger role in injection molding, reducing labor costs and increasing efficiency.

- Smart Factories: Integration of IoT technology will facilitate real-time monitoring and predictive maintenance, enhancing operational efficiency.

- Customization: Machines will increasingly focus on producing customized products efficiently, catering to consumer demand for personalized items.

2. Innovations in Materials and Processes

The advancement of new materials, including biodegradable plastics and composites, will enable more sustainable manufacturing practices. Additionally, innovations such as 3D printing integrated with traditional injection molding processes will expand design possibilities and reduce waste.

3. The Role of Automation and AI in Manufacturing

Automation and artificial intelligence (AI) will greatly influence plastic injection molding by allowing for smarter production processes. AI can optimize machine settings in real-time based on production data, improving efficiency and product quality while reducing downtime.